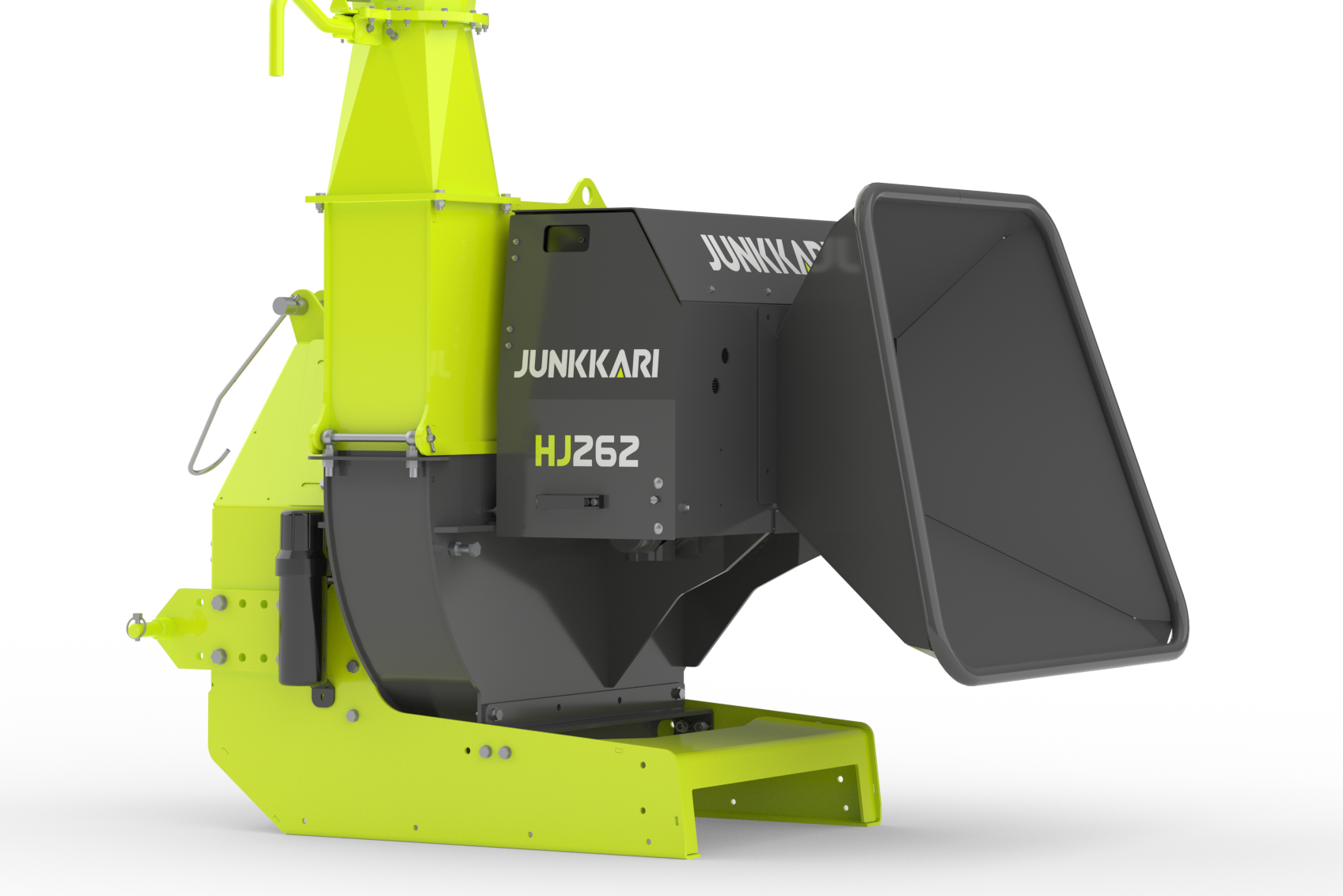

Junkkari HJ262

The Junkkari HJ262 is the only direct-feed chipper in our range. Its advantage is small and very high-quality wood chips, which is also suitable for smaller stokers. This robust chipper, which can be mounted on tractor linkages, chips wood up to 26 cm in diameter.

Very high quality wood chips

Unlike other models, the HJ262 chipper’s infeed chute is at a 90 degree angle to the blade. The chip size is smaller and the chips are very uniform. The chips break up differently from the diagonal feed and the distance between the feed rollers and the blades is as small as possible. The first-class chipping quality of the straight-feed chipper is also suitable for smaller boilers, as the chipper cuts the wood cross-sectionally.

The wide adjustment range of the blades allows the HJ262 to produce larger chips if required. The power consumption of the direct-feed model is about 20% higher than the corresponding diagonal-feed models. Under optimal conditions, the HJ262 can chop up to 30m3 per hour.

Hand feed or crane feed

The HJ262 model is equipped with two horizontal feed rollers. The advantage of two feed rollers is particularly beneficial with airy brushwood, which it is able to feed efficiently towards the blade.

In the G model, the rollers are powered by the tractor’s hydraulics and their rotation speed is steplessly adjustable with a valve on the chipper. The G, GT, GTC models are all tractor-driven chippers. The difference is that the G model requires from the tractor one pair of hydraulic blocks in addition to the PTO drive and the electric socket for the feed unit.

The GT and GTC models are equipped with their own hydraulics and do not require oil from the tractor. This is a good option when the chipper is used with more than one tractor and you do not want the oils to mix.

The G and GT models are manually fed, while the GTC model is always fed by a crane loader.

Infeed chute

Manual infeed chute

The manual infeed chute is spacious and easy to use. The front is fixed and the rear folds up easily for transport. The infeed is easily controlled by power buttons on both sides of the hopper. The standard no-stress rotation guard ensures smooth working. If the tractor RPM drops, the feed stops, the rollers retract the wood away from the blades and automatically resume feeding when the RPM rises back to the working level. A safety bar around the chute ensures operator safety by cutting off the feed if necessary.

The GTC model of the HJ262 has a crane infeed chute into which the wood should always be fed by the loader.

Crane infeed chute

The HJ262 model can be equipped with a crane infeed set. The difference to the manual feed model is the strong infeed chute and the electronic management with Wizard-C+ controller. Using the control unit and pedals, the infeed can be operated from the tractor, while also controlling the discharge chute.

Blade disc

Chop sharp

The chipper’s disc is equipped with four steplessly adjustable blades, allowing you to precisely determine the size of the chips. From the blades, the chips are transferred to the peripheral blower blades of the disc, where they are crushed, and the blades blow the chips through the chute to the desired location. Optional brush blades are available for the disc. Additionally, the chipper can be converted to a two-blade setup with optional cover plates.

No-Stress

Smooth and safe operation

In the HJ262 model, wood is always fed with the assistance of hydraulic feed rollers. This ensures that wood is transported efficiently and evenly into the chipper.

The No-Stress RPM rotation guard improves smooth operation and safety. It automatically stops the feed if the tractor’s RPM drops below a set limit and resumes feeding automatically when the RPM returns to working level.

The No-Stress feature saves the tractor’s engine and reduces fuel consumption.

Accessories

Blade options

A brush blade set is available as an accessory for the HJ262 chipper. It ensures high-quality chip production even from smaller wood material.

With optional cover plates, the disc can be converted to a two-blade model, which is ideal when using a lower-powered tractor.

The chipper chute can be made tiltable with an optional tilting hinge.

Technical information

| Feature | HJ172 | HJ252 | HJ262 | HJ320 | HJ500 | HJ550 |

|---|---|---|---|---|---|---|

| Feed opening size, cm | 20×20 | 26×26 | 26×26 | 35×35 | 45×45 | 50×50 |

| Maximum tree diameter, cm | 17 | 25 | 26 | 32 | 45* | 50* |

| Number of knives | 4 | 4 | 4 | 4 | 2 | 4 |

| Chipping capacity (m³/h) | 3-15 | 7-30 | 7-30 | 10-80 | 20-100 | 30-130 |

| Power demand kW (hp) ** | 30-50 (40-70) | 30-66 (40-90) | 40-90 (55-125) | 120-185 (160-250) | 110-185 (150-250) | +135 (+180) |

| Blade disc diameter, cm | 74 | 94 | 98 | 126 | 138 | 170 |

| Blade disc weight, kg | 106 | 172 | 240 | 520 | 650 | 930 |

| Revolutions, r/min | 540-1000 | 540-1000 | 540-1000 | 540-1000 | 540-1000 | 750-1000 |

| Blade setting, mm | 3-20 | 3-20 | 3-20 | 5-18 | 5-20 | 4-20 |

| Weight, kg | 672 (G model) 727 (GT model) | 825 (G model) 853 (GT model) 854 (GTC model) | 870 (G model) 920 (GT model) 930 (GTC model) | 2400-2900 | 3300-4200 | 7000 |

| Length in transportation position, cm | 200 | 210 (G- & GT model) 230 (GTC model) | 200 (G model) 210 (GT model) 230 (GTC model) | 280-320 | 430-483 | 705 |

| Width in transportation position, cm | 209 | 229 | 134 | 230 | 245 | 254 |

| Height in transportation position, cm | 301 | 320 | 290 | 315 | 295 | 390 |

** Knife adjustment, sharpness, knife setting, chip size and tree species have a significant impact on power demand.

pictures

Read the brochure online

An introduction to Junkkari’s extensive range of chippers can also be found in our brochure. You can browse the brochure online here.