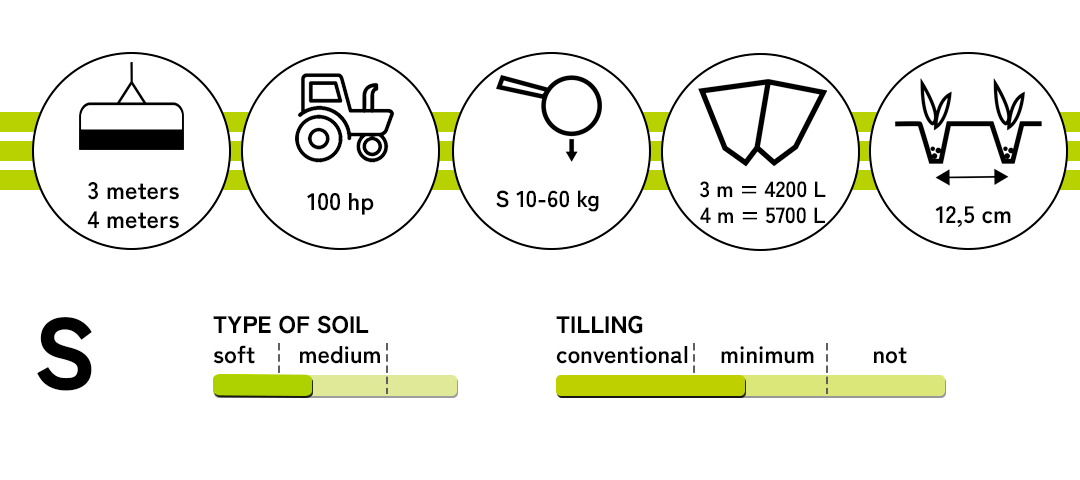

Junkkari S model

S model performs best on soft, traditionally tilled soil. It is Junkkari’s lightest combi seed drill model to pull.The coulter is designed to guide the seed and fertilizer to the correct depth in soft soils. The coulter profile supports the coulter on soil so that the sowing depth is optimal.

Coulter pressure range for the S model is 10-60 kg, and adjustment can be made hydraulically from the cabin. With the largest hoppers on the market, the S model ensures efficient and economical operation by reducing the frequency of refills.

Precise sowing for cultivated fields

The S model is available in 3 and 4-meter widths. Its concept is based on the wedge-shaped coulter, which maintains sowing depth accurately in various conditions. The long arm of the coulter allows flexibility and places the seed precisely even when soil types vary. The S model performs best on plowed and subsequently harrowed fields. On soft soil types, it is particularly important to prevent sowing too deep to maximize the yield.

Junkkari’s two-part hopper is exceptionally spacious. By turning the partition wall, the relative volumes of seed and fertilizer hoppers can be adjusted. The hopper volume is 4200 liters in the 3-meter machine and 5700 liters in the 4-meter machine.

The coulter pressure range of the S model is 10-60 kg, due to the hydraulic coulter pressure adjustment.

EQUIPMENT LEVELS

CORE

Versatile and efficient basic model

The Core equipment level offers a machine with uncompromised seeding performance, equipped with the versatile G-Wizard controller. The Core level also includes a semi-lift function, hopper guards, spring-mounted tarpaulin, following harrow and a packer with Steady drawbar as towing device.

Plus

Electronic features on top of the Core equipment level

The Plus equipment level includes all features of the Core level, but with G-Wizard+ as the controller, allowing the amount of fertiliser to be adjusted electronically using the controller. The package also includes tramline cluches for seed and fertiliser. Tramlines help with spaying the crops and spreading fertilizer but they also lead to significant savings in fertiliser and seed costs during sowing.

Pro

Pro equipment level upgrades to ISOBUS

Compared to the PLUS equipment level, the controller is replaced by an AEF-certified ISOBUS controller. In addition to the remote control of the fertiliser, the seed rate is also controlled from the ISOBUS terminal, which itself is not included in the package. The Pro level package is completed by more efficient hopper level control via two additional sensors.

Light to pull and cost-effective

The mechanical feeding system is simple, precise, and reliable. Junkkari’s feeding mechanism is built on a mechanical drive that adapts to the driving speed. The feed mechanism works reliably in all situations, even without electricity from the tractor.

The machine is light and stable, because of 20-inch wheels. Large wheels save fuel costs and maintain better soil structure due to lower surface pressure. A following harrow is standard on all Junkkari combi seed drills.

Coulters

Accurately positioning coulter

The coulter consists of a long arm and a wedge-shaped disc at its end, which closely follows the surface of the field. Seeds and fertilizer are placed in the soil at exactly the right depth next to the wedge-shaped disc.

The part of the coulter that contacts the soil in addition to the rotating disc, is equipped with a carbide tip that is highly resistant to wear. The carbide tip is designed to improve the coulter’s penetration into the soil. The coulter tube guides the seed all the way into the soil, protecting it from possible impacts against the coulter disc. This ensures that the seeds do not remain on the surface but are placed precisely at the desired depth.

The coulters are available both as a Combi version and Ferti version. The most commonly sold Combi version sows seeds and fertilizer through the same coulter in the same row with a 12.5 cm row spacing. In the Ferti version, the fertilizer is placed with separate disc fertilizer coulters between every other seed row.

Feed mechanism

The mechanical feeding system is a simple, precise and reliable choice. The Junkkari’s high precision feeding mechanism is built on a mechanical transmission that adapts to the driving speed. The ground wheel and the cardan shaft reliably transmit the operating power from the ground. The gearboxes and full-width feed rollers control the feed quantities. Feeding works reliably in all situations, even without tractor power.

FEED AMOUNT CONTROL

The feed amounts are adjusted by changing the rotation speed of the gearbox. The gearboxes help to achieve precise and consistent feed amounts even with small seed quantities, such as a few kilos of canola seed. The full-width, speed-adjustable feed roller withstands wear better and has a longer service life.

SEED ROLLERS

The two-part stud feeders on the seed side consist of a black feed roller used for grains and a yellow, narrower roller used for small seeds. When sowing grain, the rollers are connected by a red locking pin, which is released when switching to small seed sowing.

FERTILISER ROLLERS

The fertilizer rollers are full-width and equipped with larger feed holes that efficiently feed fertilizer clods as well. The full-width, speed-adjustable roller provides accuracy for small feed amounts compared to traditional roller feed, where the roller length is adjusted relative to the feed opening. The fertilizer roller is also recommended for sowing larger seeds such as peas and broad beans.

ELECTRONIC REMOTE CONTROL OF FETILISER

Electronic remote control for fertilizer is available as an optional accessory. This allows the fertilizer amounts to be adjusted during driving within the plot as soil types vary. Additionally, precision farming readiness is offered. This feature enables also the adjustment of seed and small seed quantities electronically according to a pre-planned sowing map. Precision farming readiness is built on the ISOBUS system.

Hopper

BIGGEST HOPPERS ON THE MARKET

Large hoppers save time and money by reducing the number of refills needed. The hopper is divided into two sections. By adjusting the partition wall, the relative volumes of the seed and fertilizer hoppers can be changed. Additionally, a separate small seed box is available for sowing small seeds or starter fertilizer.

AMPLE EQUIPMENT

The hopper comes standard with sieves for fertiliser, and there are steps inside the hopper to make it easier to climb in. Inside the hopper there is a measuring chart to help you estimate the amount of seed remaining. This helps to assess how to optimise seed variety replacement.

As an optional extra, cameras can be installed in the hopper. The cameras help monitor seed and fertiliser levels so that the hopper can be sown completely empty.

HUGE HOPPERS PROVIDE EFFICIENCY

The total volume of Junkkari’s 3-metre machine’s hopper is 4,200 litres and the 4-metre machine’s total hopper volume is 5,700 litres. This means a grain sowing area of about 5 ha with a 3-metre machine and about 7 ha with a 4-metre machine with one hopper.

The corresponding volumes of small seed boxes are about 285 litres on a 3 m machine and about 380 litres on a 4 m machine. The combi seed drill can also be equipped with two small seed boxes with the small seed boxes mounted both at the front and the back of the machine.

Wheels and following harrow

LARGE WHEELS SAVE SOIL AND MONEY

Large roller wheels protect the soil and save money. The roller wheels compact the seed rows and close the furrows. Sowing and closing the furrows with one drive brings significant time savings during the busy sowing season. The roller wheels also function as transport wheels, enabling the combi seed drill to be moved with full hoppers.

LIGHT TO PULL AND GENTLE ON SOIL

Junkkari’s wheels are equipped with 7.5×20” tractor-patterned tires, ensuring great functionality even on the lightest soil types. The 20-inch wheels make the machine light to pull and significantly reduce the risk of soil compaction. Large wheels save fuel costs and maintain better soil structure due to lower surface pressure.

The robust and spacious frame of the roller wheel set is easy to clean, and maintenance points are well accessible. The wheel bearings are easily lubricated thanks to the centralized lubrication system.

BOGIE WHEEL SET ADAPTS TO TERRAIN

Due to a bogie structure, the roller wheels adapt excellently to the contours of the terrain. Procession is more even, and transport is more stable than with rigid solutions. The 7.5-inch tire size is ideal for machines with 12.5 cm row spacing, because each row aligns evenly with the tires.

STANDARD FOLLOWING HARROW COMPLETES THE SOWING TRAIL

In Junkkari’s 3 and 4-meter machines, the following harrow is a standard equipment due to its undeniable benefits. The following harrow tills between the seed rows and breaks up the soil surface compacted by the wheels. A well-harrowed loose soil layer prevents crusting and silting of the surface, retaining vital moisture in the soil.

An optional half-lift function keeps the harrow on the ground even when turning at the headlands.

Controllers

ISOBUS

ISOBUS is Junkkari’s most advanced control system. The officially AEF-certified system is compatible with ISOBUS tractors and controllers. The ISOBUS interface is easy to use and can be managed from the tractor’s own display, avoiding wiring in cabin.

ISOBUS controller enables versatile alarm, monitoring, and adjustment functions. It allows the feed rate to be controlled from the cab display for up to four different hoppers, whereas standard seed drill controllers can only adjust one hopper. The ISOBUS controller’s TC-GEO support creates the possibility for precision farming, allowing sowing rates to be adjusted on a location-specific basis based on pre-prepared application maps.

G-Wizard/G-Wizard Plus

G-Wizard is Junkkari’s most popular controller, offering a wide range of monitoring and control functions for the combi seed drill. All necessary driving information is visible at a glance on the clear display. The controller is easy and logical to use. The G-Wizard Plus model additionally includes remote control of fertilizer.

Depending on the equipment level of the machine, the controller offers the following functions:

- driving speed

- 2 area counters

- hopper sensors

- axle rotation sensors

- track marker control

- tramline control

- half-lift control

- remote control of fertilizer (in G-Wizard Plus)

- gearbox monitoring

Accessories

Small seed box

The small seed box can be used to sow small seeds or starter fertilizer. Its volume is approximately 285 liters in the 3-meter machine and about 380 liters in the 4-meter machine. Combi seed drill can also be equipped with two small seed boxes, with the boxes mounted both at the front and the back of the machine. The gearbox allows stepless adjustment of small seed quantities, even with kilogram precision.

Cultivators

A combi drill can be supplemented with various cultivators.

A front leveller with one or two rows is an efficient option for hard and clay soil, where the front leveller renders the soil into crumbs and levels the surface, ensuring full germinability of the seeds. In soft soil the front leveller can be used to level the unevenness caused by the pressure of the tractor wheels.

A front harrow is a good option, if most of the soil is tilled with a disc cultivator or a cultivator. A front harrow can be used to level the plant waste from light tilling evenly and create a good seed bed for seeds.

S-tine leveller helps reduce tilling times. Depending on the soil type and humidity conditions, fields that are normally harrowed twice can be harrowed only once with the s-tine leveller. S-tine leveller can also be used to till headlands, which become compacted during turns when using the reciprocating sowing method. The s-tine leveller is available as 1-row with 25 cm row spacing and 2-row with 12.5 cm tine spacing, the 2-row has a more spacious structure, with two axles which better penetrate plant waste.

Disc cultivator is intended for direct seeding and additional tilling on hard soil after light-tilling, and for land where plant coverage in winter is the primary cultivation method. A disc cultivator has ploughing discs.

DRAW EQUIPMENT STEADY AND HEAVY

There are two different versions of draw equipment, depending on the machine’s cultivator equipment.

Steady draw equipment is intended for a machine with no cultivators or only a light, single-row cultivator, such as a front leveller, s-tine leveller or front harrow. In draw equipment, the dimensions of the towbar’s beam are 150×100 mm.

Heavy draw equipment is a more robust version intended for double-row cultivators and disc cultivators. Double-row cultivators are longer and also require a longer and sturdier towbar. The dimensions of the draw equipment’s towbar’s beam are 250×150 mm.

Both types of draw equipment are options for 3- and 4-metre machines, excluding the D model, which is always manufactured with Heavy draw equipment.

THREE DIFFERENT TOWING OPTIONS

A hook towbar that connects to the tractor’s towing hook is a clear and inexpensive option for towing a combi drill. The length of the towbar can be adjusted to suit different tractors.

Two-point linkage, which is connected to the lower links of the tractor. Two-point linkage makes the combi drill and tractor combination agile and it is possible to make tighter turns in headlands.

Packer packs the soil between the wheels of the tractor and guarantees an even sprouting surface for seeds. This helps achieve even new crop and conditions for good growth.

The packer is connected to lower links, the same as the two-point linkage, which improves the agility of the combination. The packer keeps the seeding depth stable, because in the field, the combi drill is supported by the back wheels and packer. Then the changes in the tractor height do not affect the seeding depth.

Technical information

| Feature | S300 | S400 |

|---|---|---|

| Need for direct seeding | tilled, lightly tilled | tilled, lightly tilled |

| Coulter type | single-disc coulter | single-disc coulter |

| Coulter pressure range, kg | 10-60 | 10-60 |

| Coulter pressure adjustment | hydraulic | hydraulic |

| Pressure element | tension spring | tension spring |

| Number of seed coulters | 24 | 32 |

| Row spacing, cm | 12,5 | 12,5 |

| Fertilizer placement method | fertiliser coulter/seed coulter | fertiliser coulter/seed coulter |

| Volume, litres | 4200 | 5700 |

| Partition wall | adjustable | adjustable |

| Metering device, fertiliser | feed wheel with gearbox adjustment | feed wheel with gearbox adjustment |

| Metering device, seed | 2 studded wheel with gearbox adjustment | 2 studded wheel with gearbox adjustment |

| Sieves for fertilizer | standard | standard |

| Sieves for seed | option | option |

| Half lift | option | option |

| Tyres | 7.5-20″ | 7.5-20″ |

| Brakes | option | option |

| Steady/Heavy draw equipment | steady/heavy | steady/heavy |

| Basic drawbar | option | option |

| Drawbar for lower links | option | option |

| Packer 140 cm, 10.0/75-15.3 | option | option |

| Control unit options | no control unit/G-Wizard/ G-Wizard Plus/Isobus | no control unit/G-Wizard/ G-Wizard Plus/Isobus |

| Fertilizer tramlines | option | option |

| Seed tramlines | option | option |

| Fertilizer rate remote adjustment | option (G-Wizard Plus/Isobus) | option (G-Wizard Plus/Isobus) |

| Seed rate remote adjustment | option (Isobus) | option (Isobus) |

| Precision farming solution | option (Isobus) | option (Isobus) |

| Additional hopper monitoring | option | option |

| Hydraulic track marker | option | option |

| Single-row front leveller | option | option |

| Double-row front leveller | – | – |

| Double-row s-tine leveller | – | – |

| Disc cultivator | – | – |

| Front harrow | option | option |

| Small seed and start fertiliser device | option | option |

| Working width, cm | 300 | 400 |

| Transport width, cm | 300 | 400 |

| Filling height in working position, cm | 216 | 216 |

| Length, cm | 474-650 | 474-650 |

| Weight, kg | min. 2500 | min. 3100 |

| Power demand, hp | 80 | 100 |

Pictures

videos

Read the brochure online

An introduction to Junkkari’s extensive range of seed drills can also be found in our brochure. You can browse the brochure online here.