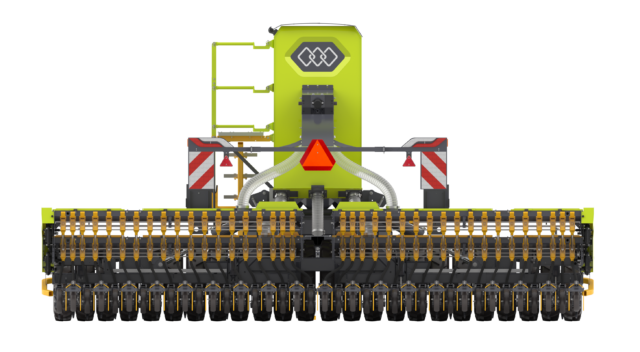

Junkkari W model

The W model is the biggest and most efficient combi seed drill in its class. Sowing speed with the W model is exceptional, and because of low requirements for hydraulics, this combi seed drill can easily be towed also with a smaller tractor. The extremely spacious hopper of 7150 liters reduces the number of refills needed and therefore brings savings both in fuel costs and for environment.

Depending on the model, the W model has a working width of 6 or 7 metres. Both models have a compact transport width of 3 metres thanks to their ingenious design. The reliable and easy-to-use W model is suitable for all types of soil.

Precise feeding

The W machine is suitable for all soil types from cultivated to lightly tilled soil. W model can also be used for direct sowing to a limited extent. The disc cultivator is sold as an accessory and it reduces the need for pre-sowing tillage and enables sowing into stubble.

The W model sows precisely and evenly. The feeding system is powered by the roller wheels separately for the right and left side. This compensates for the speed difference that occurs in curves. Thanks to the ingenious design, the hopper augers ensure a consistent material feed throughout the sowing process. The feed rollers rotate only when the machine is moving, ensuring that there are no delays in feeding.

Extremely efficient machine with lower power requirements

W model takes its power transmission from roller wheels, so the only hydraulic need is 20 l/min required by transfer augers. Power requirement from tractor is low, starting from 150 hp. Speed of feed system adapts to driving speed. You can operate W machine with a smaller tractor, and technical solutions do not limit sowing speed.

W model has significantly lower requirements for tractor compared to pneumatic competitors. It does not require continuously variable transmission, variable displacement hydraulics, or high continuous hydraulic output.

Coulters

Patented leaf spring solution

W machine has a strong double disc coulter. The coulter opens a perfect seed furrow, and the guide between the discs ensures seeds reach the bottom. The wheel behind maintains working depth and closes the furrow. Finally, the following harrow tills between the seed rows and breaks up the soil surface compacted by the wheels. Coulters are spaced 15.9 cm apart, and the coulter pressure range is 20-100 kg.

Junkkari has patented the leaf spring coulter solution for the W model, achieving a sturdier and more durable coulter attachment and pressure. Coulter pressure and working depth are easily adjusted by changing the number of lamellas. In the sowing position, the hydraulically weighted wings have a +/-10 cm movement range. This allows the machine to adapt to field contours and maintain consistent sowing depth across the entire width of the machine.

Material transfer

The material transfer from main hopper to wing hopper and from there to each feeding device is simple and straightforward. Seeds move from main hopper by gravity, and fertilizer is assisted by a screw conveyor to transport screws, which then carry material to feeding system. This ensures consistent material flow throughout sowing process.

Mechanical feeding system is simple, precise, reliable, and a trustworthy choice for farmers. Junkkari’s feeding mechanism is built on a mechanical drive that adapts to driving speed. Roller wheels transmit drive reliably from ground, and gearboxes and full-width feed rollers manage feed quantities. Feeding works reliably in all situations, even without electricity from tractor.

FEED AMOUNT CONTROL

The feed amounts are adjusted by changing the rotation speed of the gearbox. The gearboxes help to achieve precise and consistent feed amounts even with small seed quantities, such as a few kilos of canola seed. The full-width, speed-adjustable feed roller withstands wear better and has a longer service life.

SEED ROLLERS

The two-part stud feeders on the seed side consist of a black feed roller used for grains and a yellow, narrower roller used for small seeds. When sowing grain, the rollers are connected by a red locking pin, which is released when switching to small seed sowing.

FERTILISER ROLLERS

The fertilizer rollers are full-width and equipped with larger feed holes that efficiently feed fertilizer clods as well. The full-width, speed-adjustable roller provides accuracy for small feed amounts compared to traditional roller feed, where the roller length is adjusted relative to the feed opening. The fertilizer roller is also recommended for sowing larger seeds such as peas and broad beans.

ELECTRONIC REMOTE CONTROL OF FETILISER

The W model comes standard with an electronic remote control that allows fertiliser rates to be changed on the move within the plot as the soil type varies. ISOBUS includes precision farming capability where, in addition to fertiliser, seed and small seed rates are electronically adjustable according to a pre-planned crop map.

Hopper

The largest hopper on the market

Large, combined capacity of 7150-liter combi hopper increases efficiency by minimizing time spent on refilling. Large hoppers save time and money by reducing number of refills needed.

Hopper has a fixed partition wall, dividing space between fertilizer and seed in a 60/40 ratio. Hopper includes an ergonomic and safe working platform and an easy-to-use spring-loaded cover. Sieves are standard in hoppers. Hopper fill height is 3.4 m.

There are two conveyor screws inside the hopper and they transport fertilizer to wing hoppers. Excess fertilizer returns to fertilizer hopper with the other screw. Rotation speed of fertilizer screw can be adjusted steplessly.

ISOBUS

ISOBUS

ISOBUS is Junkkari’s most advanced control system. The officially AEF-certified system is compatible with ISOBUS tractors and controllers. The ISOBUS interface is easy to use and can be managed from the tractor’s own display, avoiding wiring in cabin.

ISOBUS controller enables versatile alarm, monitoring, and adjustment functions. It allows the feed rate to be controlled from the cab display for up to four different hoppers, whereas standard seed drill controllers can only adjust one hopper. The ISOBUS controller’s TC-GEO support creates the possibility for precision farming, allowing sowing rates to be adjusted on a location-specific basis based on pre-prepared application maps.

Accessories

Small seed box

For sowing grass and root crops, the seeder can be equipped with a blower-type small seed box. The small seed box is mounted on the machine body and the hoses are brought to the front of the wheels to the spreading nozzles. It is hydraulically operated and requires one hydraulic block and a free return to function.

Front leveller

The front leveller renders the soil and tyre tracks even. The front leveller is of a 1-row design and is attached to both wing blocks in front of the wheels. The front leveller is a good option, especially on soft ground where the tractor’s twin wheels do not render the ground over the full width of the machine. The front leveller evens out the seedbed for the wheels and coulters.

Disc cultivator

A disc cultivator is also available for stubble sowing and seedbed shaping. The disc cultivator has a 2-row design with ploughing discs with a disc diameter of 330 mm. When equipping the machine with a disc cultivator, the increasing tractor power requirement must be taken into account.

Technical information

| Feature | W600 | W700 |

|---|---|---|

| Need for direct seeding | tilled, lightly tilled | tilled, lightly tilled |

| Coulter type | double-disc coulter | double-disc coulter |

| Coulter pressure range, kg | 20-100 | 20-100 |

| Coulter pressure adjustment | hydraulic, lamella | hydraulic, lamella |

| Pressure element | tension spring | tension spring |

| Number of seed coulters | 38 | 44 |

| Row spacing, cm | 15,8 | 15,9 |

| Fertilizer placement method | seed coulter | seed coulter |

| Volume, litres | front hopper 3350, rear hopper 3800 | front hopper 3350, rear hopper 3800 |

| Partition wall | fixed | fixed |

| Metering device, fertiliser | feed wheel with gearbox adjustment | feed wheel with gearbox adjustment |

| Metering device, seed | 2 studded wheel with gearbox adjustment | 2 studded wheel with gearbox adjustment |

| Sieves for fertilizer | standard | standard |

| Sieves for seed | standard | standard |

| Half lift | – | – |

| Tyres | 7.5×20″ | 7.5×20″ |

| Brakes | option | option |

| Steady/Heavy draw equipment | – | – |

| Basic drawbar | – | – |

| Drawbar for lower links | Drawbar for lower links as option | Drawbar for lower links as option |

| Packer 140 cm, 10.0/75-15.3 | – | – |

| Control unit options | Isobus | Isobus |

| Fertilizer tramlines | option | option |

| Seed tramlines | option | option |

| Fertilizer rate remote adjustment | option | option |

| Seed rate remote adjustment | option | option |

| Precision farming solution | option | option |

| Additional hopper monitoring | Camera (2 pcs) | Camera (2 pcs) |

| Hydraulic track marker | – | – |

| Single-row front leveller | option | option |

| Double-row front leveller | – | – |

| Double-row s-tine leveller | option | option |

| Disc cultivator | option | option |

| Front harrow | – | – |

| Small seed and start fertiliser device | option | option |

| Working width, cm | 600 | 700 |

| Transport width, cm | 300 | 300 |

| Filling height in working position, cm | 320 | 320 |

| Length, cm | 850-900 | 850-900 |

| Weight, kg | 6800-8300 | 7500-9000 |

| Power demand, hp | 150+ | 150+ |

pictures

videos

Read the brochure online

An introduction to Junkkari’s extensive range of seed drills can also be found in our brochure. You can browse the brochure online here.